Welcome to

DIXON AUTOMATIC TOOL, INC.

A Recognized Leader in Automated Assembly Products and Services

Stay Competitive

Take advantage of Dixon’s Auto-fed Screwdrivers, Nut Drivers, Auto-fed Part Placers, Pick & Place Mechanisms, Feed Systems, Assembly Work Cells, including Robotic and Vision Applications. Each of our products are manufactured to assure quality, accuracy, and dependability for constant assembly production. DIXON is committed to providing you with satisfactory solutions to your assembly needs. Contact us today and we’ll help you find the best product for your assembly needs.

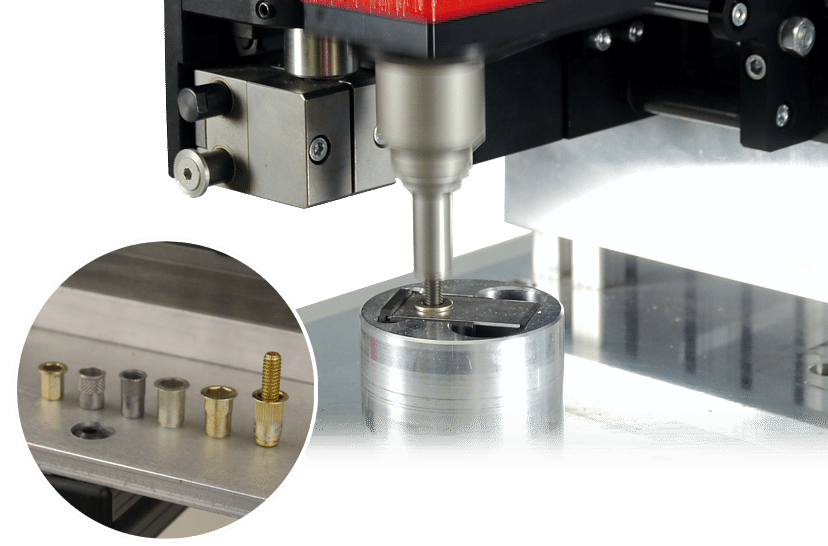

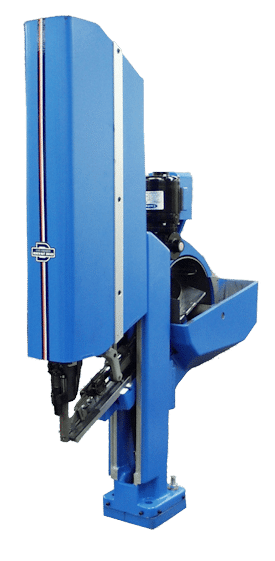

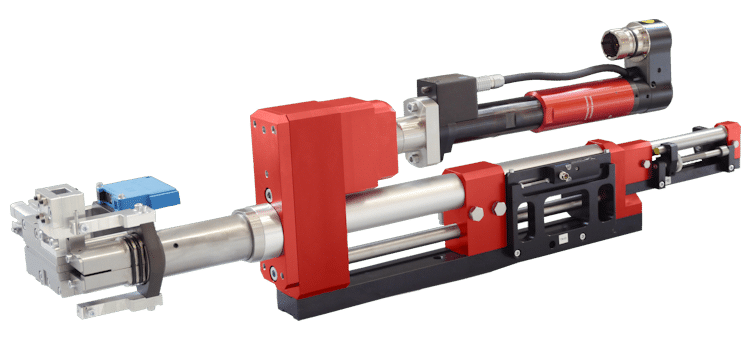

Automatic Screwdrivers

Standard and custom auto-fed screw/nut drivers and, screw/nut driver stations.

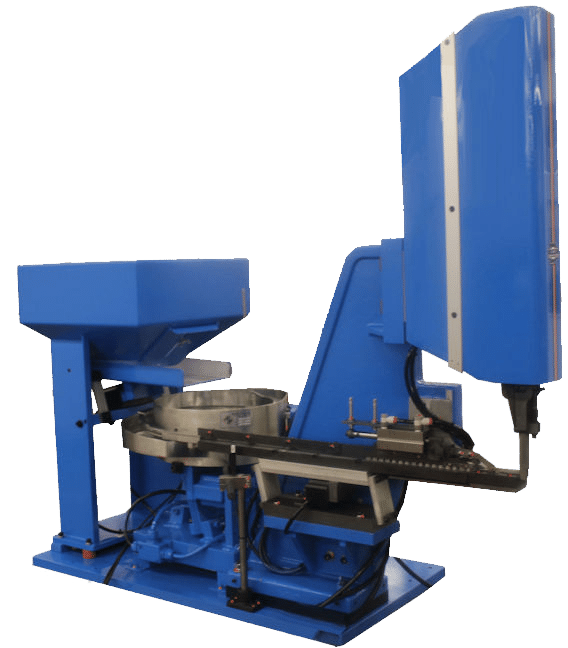

Part Placers

Standard and custom auto-fed part placers, including special pick & place part placing stations.

Robotic End Effectors

Equipped with vision systems to recognize piece parts, insertion points, and verification of the production process at the work cell.

Get To Know

DIXON AUTOMATIC TOOL, INC.

Dixon Automatic Tool, Inc. is a privately-owned company located in Rockford, IL. Our Company is the outgrowth of Dixon Research, Inc., founded in 1946 by the late Paul H. Dixon. Dixon Research specialized in the development of weapons with high-speed ammo feed systems for the military. As this technology developed, we transitioned to industrial applications that led to re-incorporating our company as Dixon Automatic Tool, Inc. in 1952.

Our staff have always been focused on engineering and the creation of new products to improve productivity. Our products are the result of years of design and development work involving parts handling for automated assembly. Dixon has accumulated a wealth of experience and knowledge in assembly technology. Our engineering background allowed us to specialize on developing automatic self-fed screwdrivers, nut drivers, part placers, feed systems, part orienting and placement of a wide range of component piece parts. We also offer a line of semi-automatic work cells.